Since 1996 in the system engineering sector

SubliMac

System construction Sublimation

System construction Sublimation

What is the sublimation process?

The heat sublimation process transfers graphic images (with a special decorated sublimatic transfer film) onto profiles, panels and semi-finished metal products.

This technique makes it possible to transfer and fix a series of graphic effects and decorations onto metal products, such as reproducing the wood effect finish.

The objects to be subjected to sublimation must be previously treated (cleaning the surface) and painted (with powder paint), in order to guarantee correct sublimation and a quality finished product.

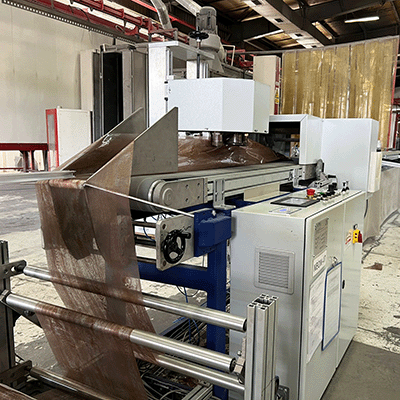

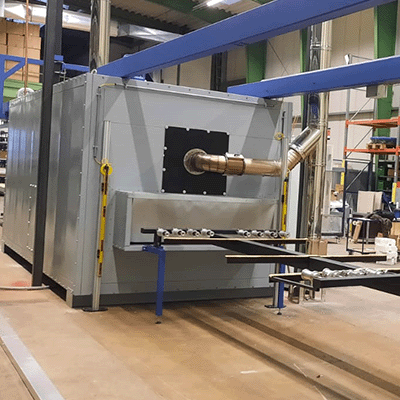

The painted object is then wrapped with pre-printed transfer film which is made to adhere perfectly to the substrate through a vacuum suction process of the air, to then be placed in the oven at a temperature of 200° – 220° for a pre-set time, during which the decoration present on the film sublimates (passes from the solid to the gaseous state), being permanently absorbed within the layer of previously sprayed paint.

The transfer film is then removed from the object subjected to sublimation, where the decoration perfectly penetrated into the layer of varnish is thus visible.

The result obtained is a high quality print, resistant to atmospheric events (UV rays, temperature changes), to wear/corrosion and easy to care for and clean.

CONTACT US

Our Company

SUBLIMAC

Sublimac was born following the experience acquired since 1996 in the system engineering sector, industrial automation and maintenance of industrial systems in various sectors, including that for the treatment of surfaces, in particular that of sublimation.

Sublimac has specialized in the construction and installation of machinery and systems for the decoration of profiles and panels with a wood effect finish, which apply the hot sublimation technique.

The systems are designed trying to best respond to the production needs of users, renewing, integrating, expanding, where possible, new technologies and accessories useful for the production of a quality finished product.

Our Systems

INDUSTRIAL SOLUTIONS

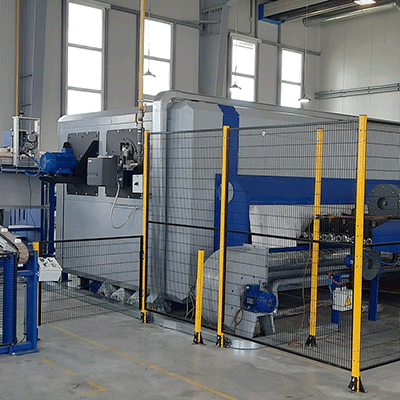

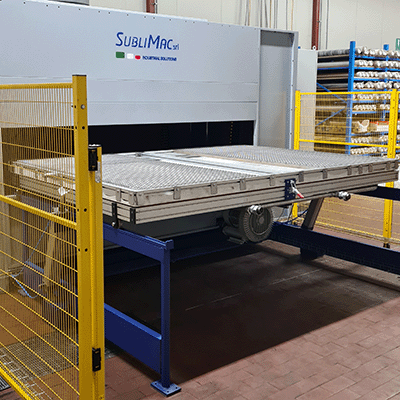

Sublimation system: with trolley, side loading of profiles, side loading of plates, front loading of profiles.

Automatic sublimation system for flat sheets composed of an automatic bagging machine and a 2 or 3 field sublimation oven.

Our Services

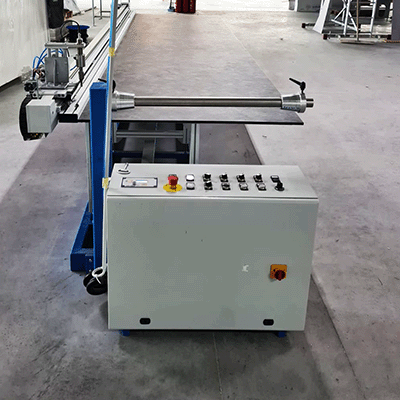

Sublimac is available to its customers to design and develop automation panels for the management of industrial systems and their own utilities in the field.

The electrical panels are mainly equipped with plc and software for the control and management of the various processing phases of the production lines.

In order to lengthen the life of the machines, limit the emission of new materials into the environment, contain costs and quickly have efficient machines available, with a view to progressive automation, Sublimac also offers the practice of modernizing / revamping existing production lines.

Revamping means the replacement of worn parts or the integration with improved components in order to create a renewed machine.

The machines involved, which operate mainly in the manufacturing sector, are equipped with computerized systems and managed through appropriate sensors and drives.

Also included are devices for man-machine interaction, i.e. all those tools that facilitate and improve the operator’s work and integrate data into the factory computer system.

Finally, retrofit operations must meet and be in line with safety parameters.